Heating cabled insulation jackets are used when mechanical equipment has following features;

Many viscous and paste-like fluids that are difficult to pump are subjected to more severe consistency than desired due to the reduction of the heat level in some areas of the production line. Insulation jackets with heating cables protect the desired consistency of the reinforcement heat fluid and eliminate the risk of pausing on the production line.

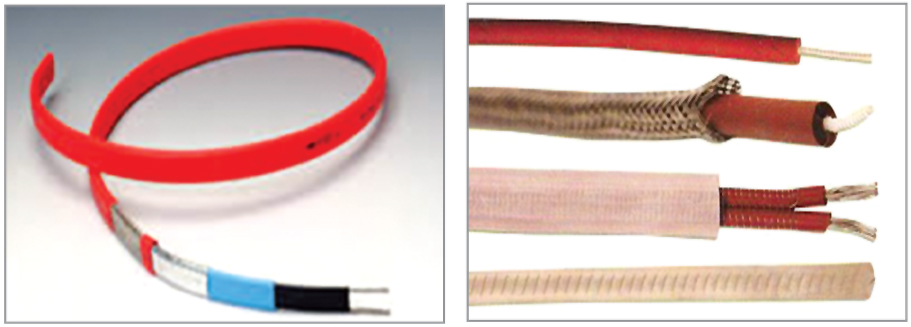

In our insulating jackets with heating cables, we have alternative cable options that can respond to every need in the industrial field.

Sleeve

Thermostat

Termination Kit

Boat

Control Panel

Products can be varied and quoted depending upon the project.

Please contact us.